When you are managing a commercial build or a large scale retrofit, the building envelope is your most critical asset. It is not just about the “look” of the structure. For architects and developers, the exterior facade must solve a complex equation of non-combustibility, thermal performance, wind load resistance, and long term maintenance costs.

The pressure to deliver a high performance building that meets increasingly strict Canadian building codes while staying on budget is a common challenge. If you have dealt with the fallout of poor material specification such as delamination, faded finishes, or failing thermal barriers you know that the “cheapest” option often becomes the most expensive over a ten year cycle.

This guide provides a honest, consultant level deep dive into the most reliable commercial exterior panels available today. We will move past the marketing fluff and look at the engineering and lifecycle data you need to specify the right system for your project.

The Engineering Behind Modern Commercial Exterior Panels

In commercial construction, the building envelope acts as a sophisticated barrier. Unlike residential siding, commercial wall cladding must be engineered to withstand higher wind pressures, especially on high rise structures, and must comply with stringent fire safety standards.

Compliance with the Ontario Building Code (OBC) is mandatory for any project within the province. Specifically, Part 3 of the OBC governs fire protection and occupant safety for large buildings, often requiring cladding materials to be tested under the CAN/ULC-S134 standard for fire spread.

Most modern commercial buildings utilize a Ventilated Rainscreen (VRS) principle. This system creates an air gap between the cladding panels and the weather resistant barrier. This gap allows for pressure equalization and ensures that any moisture that penetrates the outer layer is evaporated or drained away, protecting the structural integrity of the building for decades.

Categorizing Commercial Wall Cladding by Performance

Selecting the right material requires balancing architectural vision with functional necessity. Here is a breakdown of the industry standard materials used in high traffic and high rise commercial environments.

Aluminum Composite Material (ACM/ACP): Precision and Versatility

Aluminum Composite Panels are the workhorse of modern commercial architecture. Consisting of two thin aluminum skins bonded to a fire retardant mineral core, ACM offers a level of flatness and “clean” joinery that other materials struggle to match.

- Technical Depth: ACM panels are favored for their ability to maintain extreme flatness over large spans. This prevents “oil canning” which is a common visual defect in thinner metal sidings.

- When to specify: Ideal for corporate branding and modern office towers where a sleek finish is required.

- Seismic and Thermal Movement: Engineered ACM systems include specialized clips that allow the panels to expand and contract without stressing the fasteners or the building frame.

Solid Aluminum Plate Systems: The Ultimate Exterior Solution

If your project is in a high traffic urban area or requires maximum impact resistance, Solid Aluminum Plates are the gold standard. These are not composite; they are solid sheets of architectural grade metal, typically 3mm to 4mm thick.

- The Ultimate Solution: While Aluminum Plates represent a higher upfront investment, they are virtually indestructible. They are 100% non combustible, making them the safest choice for high rise structures where fire code compliance is the top priority.

- Durability: These systems are impervious to the dings and scratches that occur at street level in dense urban environments. Their lifecycle often exceeds 50 years with minimal maintenance.

Insulated Metal Panels (IMP): The All-in-One Thermal Solution

For industrial hubs, warehouses, and cold storage, Insulated Metal Panels are often the primary choice. These panels provide the exterior skin, the insulation, and the interior finish in a single component.

- Thermal Performance: IMPs offer exceptional R values (often exceeding R 7 per inch) and provide continuous insulation. This is critical for meeting the energy efficiency requirements of the National Energy Code for Buildings (NECB).

- Installation Efficiency: Because they combine multiple layers into one panel, they significantly reduce on site labor and speed up the construction schedule.

Learn more: Ultimate Guide to Insulated Metal Panels

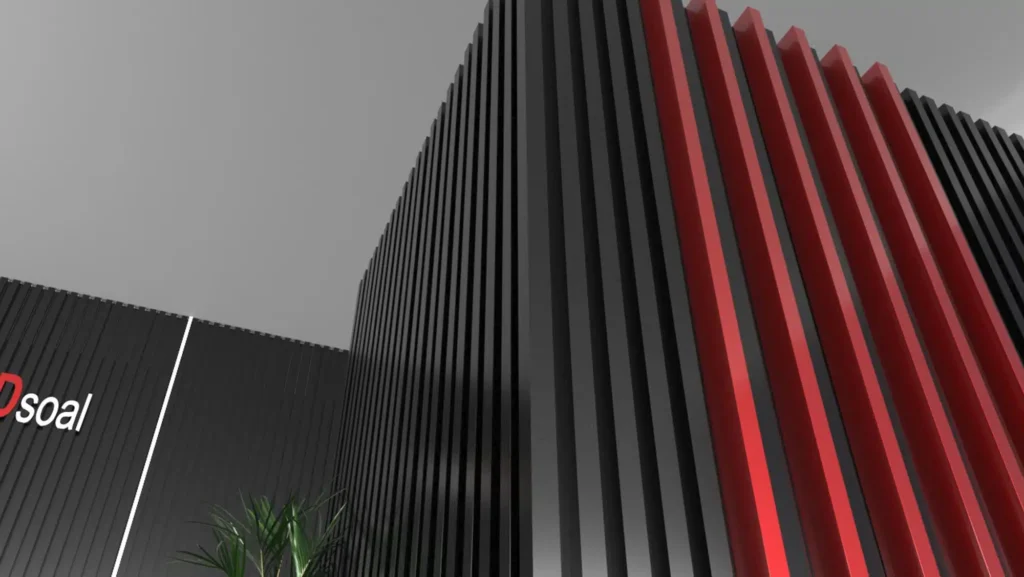

Fluted Aluminum Panels: Innovation in Architectural Aesthetics

For architects seeking to bridge the gap between high end aesthetics and industrial durability, Fluted Aluminum Panels represent a significant innovation in the Canadian market. These panels are engineered for both interior and exterior applications, offering a textured, three dimensional appearance that traditional flat panels cannot achieve.

Nortem’s fluted aluminum wall panel is the first of its kind in Canada to provide a true commercial grade solution that meets rigorous safety and performance standards. These panels have successfully passed the following critical reports:

- Fire Rating Test (ASTM E84): Ensuring superior flame spread and smoke developed indices for indoor and outdoor safety.

- Non-Combustibility Test (ASTM E136-22): Certified as a non combustible material, essential for high rise and high density commercial zones.

- Solar Transmission and UV Test (ASTM 903-12): Proven to maintain finish integrity and color stability despite constant exposure to harsh Canadian sunlight.

These panels are the ideal choice for developers looking for a durable, non combustible alternative to wood or plastic fluting that will not warp, rot, or fade over time.

Architectural Aluminum Siding

In hospitality or boutique office designs, there is a growing demand for the aesthetic of traditional wood planks. Architectural Aluminum Siding provides this organic look but with the fire rating and durability required for commercial use. It offers a premium, dent resistant alternative that maintains its architectural profile without the maintenance burden of real timber.

Technical Comparison: Material Selection for Commercial Building Facades

|

Feature |

ACM / ACP | Solid Aluminum Plate | Fluted Aluminum |

Insulated Metal Panels |

|---|---|---|---|---|

| Primary Use | High rise / Corporate | High traffic / Premium | Aesthetic Accents | Industrial / Cold Storage |

| Weight | Very Lightweight | Moderate | Lightweight | Moderate to Heavy |

| Fire Rating | FR Core (Class A) | Non combustible | Non combustible | High R Value / Fire rated |

| Impact Resistance | Moderate | Extreme | High | Moderate |

| Relative Cost | Mid Range | High (Premium) | Mid to High | Economical for large scale |

Critical Specifications for Commercial Building exterior wall materials

Wind Load and Structural Engineering

Commercial building exterior wall panels must be calculated for specific wind loads. High rise projects in cities like Toronto face extreme pressures at higher altitudes. Specifying the correct fastening system, whether it is a dry joint or wet seal system, is just as important as the panel material itself.

Finish Durability and UV Resistance

Color retention is a major concern for commercial building facade panels. Most premium metal panels use a PVDF (Kynar 500) coating. This finish is engineered to resist chalking and fading for 20 to 30 years, ensuring the building maintains its appearance without the need for repainting.

Fire Safety and Code Compliance

In Canada, the National Building Code (NBC) dictates the use of non combustible cladding for buildings over a certain height. It is vital to ensure your selected panels have passed the CAN/ULC S134 test for fire spread. Solid aluminum and mineral core ACM are the primary solutions to satisfy these safety requirements while protecting the occupants.

Proven Expertise: 500+ Commercial Projects Across Ontario

Selecting a cladding partner is a matter of risk management. Experience in the local market ensures that your provider understands the nuances of Ontario weather and Canadian logistics.

At Nortem, we have successfully completed over 500 commercial projects across Toronto Greater Area and Ontario. Our Portfolio showcases a diverse range of high profile installations, proving our ability to handle complex architectural requirements for top tier clients. Notable projects include facade solutions for global brands and local landmarks such as Amazon, Longo’s, and McDonald’s, as well as specialized architectural work for BMO and Subaru.

Each of these projects required a specific approach to material fabrication and site management, ensuring that the building envelope met both the aesthetic vision of the architect and the performance needs of the owner.

Navigating the Supply Chain: From Fabrication to Installation

One of the biggest risks in commercial exterior projects is the fragmentation of the supply chain. If the designer, the fabricator, and the installer are from different companies, errors in shop drawings or site measurements can lead to massive delays.

Working with a single source facade solution provider, one that handles everything from CNC fabrication to final installation, removes this friction. It ensures that the panels arriving on site are precision engineered to fit the structural steel perfectly.

Conclusion: Future Proofing the Commercial Exterior

Choosing a commercial cladding system is a decision that impacts the building’s operational budget for decades. While traditional materials might offer a lower initial price, high performance metal systems like aluminum plate and ACM provide the durability, safety, and aesthetic longevity that commercial developers require.

At Nortem, we specialize in the engineering and installation of these high performance systems across Canada. Whether you are an architect looking for technical shop drawings or a developer needing a reliable installation team, we provide the expertise to ensure your building envelope is a success.

Get a Professional Consultation and Estimate

Ready to specify the right cladding for your next commercial project? Our team of experts is available to provide technical guidance, samples, and detailed cost estimates to ensure your building envelope meets every performance and budget requirement.