Whether you are an architect specifying a high-rise or a contractor planning a storefront, this aluminum composite panel guide provides the technical depth and real-world insights needed for a successful installation. In the modern construction landscape of the Greater Toronto Area, ACM cladding has become the gold standard for achieving a sleek, durable, and low-maintenance building envelope.

What Exactly is an Aluminum Composite Panel?

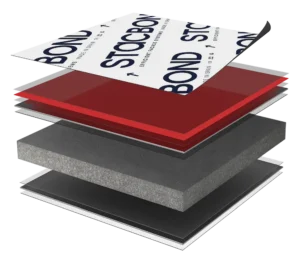

To understand why this material is so popular among Northern builders, we have to look at its construction. An aluminum composite panel is essentially a sandwich. It consists of two thin sheets of aluminum, known as skins, permanently bonded to a central core material.

This composite structure is the secret to its success. By using two outer layers of metal, the panel gains the rigidity of a solid metal plate. However, because the core is lightweight, the overall product is significantly easier to transport and install on busy urban job sites.

- Skin Thickness: Typically 0.5mm for architectural grade.

- Total Thickness: 4mm is the standard for aluminum composite panels in the Canadian market.

Aluminum Composite Panel Details and Composition

The technical specifications of these panels are what separate professional grade cladding from basic signage materials. Typically, the aluminum skins are approximately 0.5 mm thick. The total thickness of the panel usually ranges between 3 mm and 6 mm, with 4 mm being the standard for most commercial architectural applications in Ontario.

The exterior skin is treated with a high performance coating, usually PVDF (Polyvinylidene Fluoride) or FEVE resins. These coatings are vital for the Canadian climate because they protect the aluminum from intense UV radiation in the summer and corrosive de-icing salts in the winter.

The Fire Safety Reality: PE vs. FR vs. A2

Under the National Building Code of Canada (NBC), the core material is the most important specification for safety.

- Standard PE (Polyethylene) Cores: The PE core is made of a plastic material. It is lightweight and cost effective. While it is excellent for signage, interiors, or low rise residential projects, it is combustible.

- FR (Fire Retardant) and A2 (Non-Combustible) Cores: For any high rise project or commercial facade, fire safety is the absolute priority. FR cores contain mineral additives to slow flame spread. However, for maximum compliance, the A2 core is virtually non combustible.

Note: Ensure your supplier provides testing to CAN/ULC-S134 standards to meet Ontario fire regulations.

Why Architects Choose ACM Cladding

Canada’s climate presents unique challenges: humid summers, sub zero winters, and high wind pressures on skyscrapers. Aluminum composite material excels in these conditions.

Handling the Freeze Thaw Cycle

Materials like brick and mortar can crack when moisture enters a pore and freezes. Aluminum composite panels are non porous. They provide a seamless barrier that shrugs off moisture, preventing the structural damage often seen in older Toronto buildings.

Color Consistency

PVDF coatings ensure that the color you choose today stays the same for 30 years, despite the harsh UV exposure of Ontario summers.

Weight and Structural Savings

One of the biggest challenges in construction is managing the “dead load” of a building. ACM cladding provides the premium look of heavy plate metal at a fraction of the weight. This often allows for lighter, less expensive structural framing.

How Does ACM Stack Up Against Other Materials?

| Feature | ACM Panels | Brick / Masonry |

Fiber Cement |

|---|---|---|---|

| Weight | Very Low | High | Medium |

| Moisture Absorption | 0% | High (Porous) | Moderate |

| Freeze-Thaw Resistance | Excellent | Prone to Cracking | Average |

Professional Installation: The Rain Screen System

The way a panel is installed is just as important as the panel itself. In the past, builders relied on “Wet Seal” systems where every joint was filled with silicone. While effective initially, silicone eventually shrinks, cracks, and attracts dirt, creating a maintenance nightmare and potential leak points.

The modern solution is the Dry Seal Rain Screen System. This engineering approach treats the building envelope as a multi-layered defense. Instead of trying to block water at a single point, a rain screen uses a series of aluminum extrusions and a “ventilated cavity” behind the panels.

The Real Cost of Aluminum Composite Panels in 2026

When budgeting for a project in 2026, remember that “price per square foot” is only one part of the equation. As a consultant, I ask my clients to look at the Total Life Cycle Cost.

While a vinyl or fiber cement wall is cheaper on day one, an ACM wall requires zero painting and zero sealing for 30 years. When you factor in the speed of installation and the increase in property value, aluminum composite panels often offer the best return on investment for commercial owners.

You can send your inquiry here, and our expert team will assist you in estimating the cost of your project.

Maintenance for the Canadian Climate

To keep your panels looking pristine, we recommend a simple “Spring Cleaning.”

- Rinse: Use a low pressure hose to remove winter salt spray.

- Wash: Use a soft cloth and a pH neutral detergent to wipe away any stubborn grime.

- Avoid: Never use abrasive brushes or strong organic solvents, as these can damage the specialized PVDF coating.

Project Spotlight: Commercial Excellence

A recent project that perfectly illustrates the power of ACM is a Domino’s Pizza location where we provided a full-service cladding solution. Fast-food franchises require a very specific brand identity that must be consistent across all locations, necessitating high-precision fabrication.

For this location, our team handled everything from the initial site measurements to the final installation. We utilized a custom color-matched system to meet Domino’s corporate branding requirements. By using a dry-seal rain screen system, we ensured the building would remain moisture-free while maintaining the sharp, clean lines that the brand is known for. This project highlights our ability to deliver a turn-key solution for commercial retail where speed of installation and visual impact are paramount.

The Bottom Line

Aluminum composite panels are more than just siding; they are an engineered system. While this aluminum composite panel guide provides a high-level overview, every project has unique requirements regarding wind load and fire code.

Ready to See the Real Thing?

If you are ready to move from research to reality, we invite you to explore our high-performance material options.

- View the STACBOND ACM catalog.

- Check the ALUCOBOND ACM specifications.

- Request a Sample Kit or Get a Quote from our Concord office today.