Composite panels have revolutionized the world of construction and design, offering a harmonious blend of aesthetics, versatility, and functionality. From residential to commercial projects, these panels have found their way into various applications due to their durability, insulation properties, and sleek appearance. In this comprehensive blog, we delve into the diverse types of composite panels, their unique characteristics, and the wide range of uses that make them an indispensable choice in contemporary architecture.

Types of Composite Panels

1. Aluminum Composite Panels (ACPs):

Aluminum composite panels, or ACPs, consist of two aluminum sheets bonded to a core material, usually made of polyethylene or fire-resistant mineral. ACPs are renowned for their lightweight nature, making them easy to handle and install. They boast excellent weather resistance, making them suitable for both exterior and interior applications. Architects and designers often appreciate ACPs for their limitless design possibilities and color variations.

2. Insulated Metal Panels (IMPs):

Insulated metal panels, or IMPs, are known for their exceptional thermal insulation properties. These panels consist of two metal faces with a foam insulation core in between. IMPs offer energy efficiency and structural stability, making them ideal for applications where insulation is paramount, such as cold storage facilities or energy-efficient buildings.

3. Fiber-Reinforced Polymer (FRP) Panels:

Fiber-reinforced polymer panels, also known as FRP panels, are composed of a polymer matrix reinforced with fibers such as glass, carbon, or aramid. These panels are lightweight, corrosion-resistant, and offer high strength-to-weight ratios. They find application in industries ranging from aerospace to automotive, as well as architectural features like facades and decorative elements.

4. High-Pressure Laminate (HPL) Panels:

High-pressure laminate panels, or HPL panels, are crafted by layering resin-impregnated paper sheets under high heat and pressure. HPL panels are renowned for their durability, resistance to impact, and scratch resistance. They are often used in cladding, partitioning, and interior applications where robustness is essential.

5. Wood-Plastic Composite (WPC) Panels:

Wood-plastic composite panels, or WPC panels, combine wood fibers or particles with thermoplastics to create a versatile material. WPC panels offer the appearance of wood with the durability and moisture resistance of plastic. They are used for decking, fencing, and even interior wall cladding due to their eco-friendly attributes and low maintenance requirements.

6. Phenolic Panels:

Phenolic panels are manufactured by impregnating layers of paper with phenolic resins and then curing them under heat and pressure. These panels are renowned for their fire resistance, durability, and weather resistance. Phenolic panels find extensive use in outdoor cladding systems, as well as decorative interior elements.

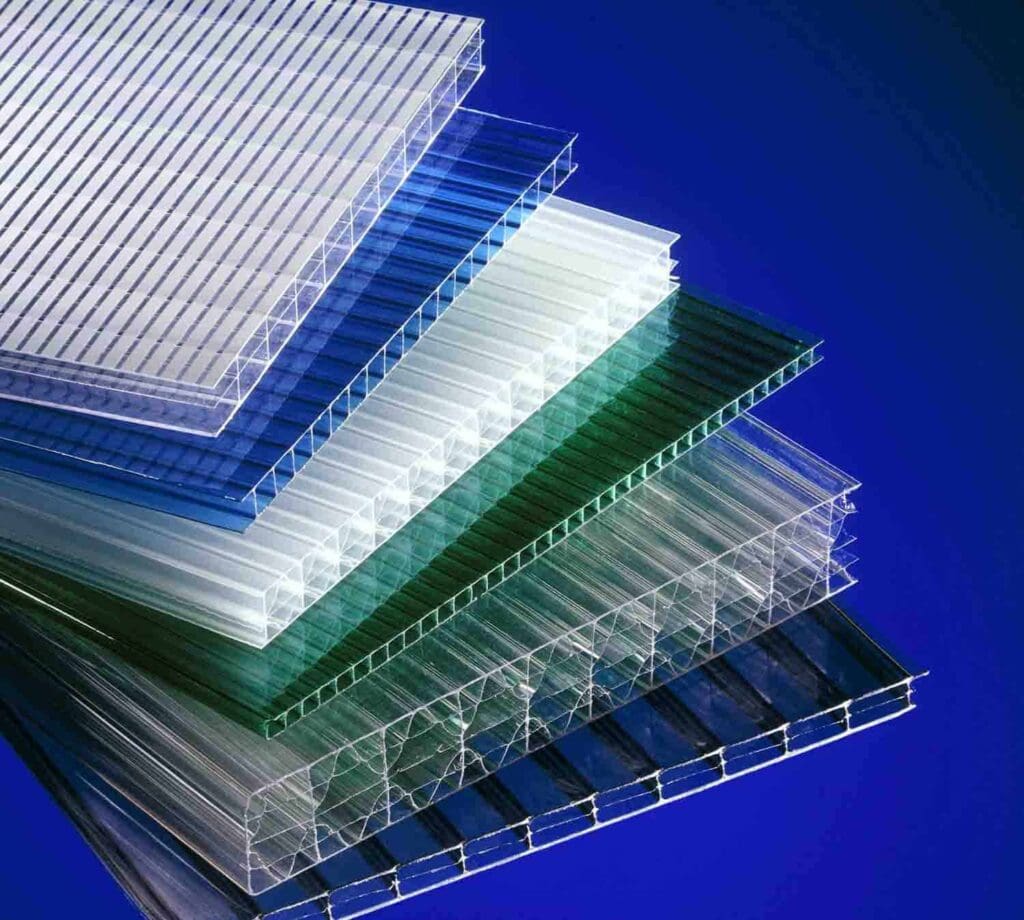

7. Polycarbonate Panels:

Polycarbonate panels are transparent or translucent composite panels made from polycarbonate thermoplastic. They are lightweight, impact-resistant, and offer excellent thermal insulation properties. Polycarbonate panels are often used for roofing, skylights, and translucent wall panels, allowing diffused natural light to illuminate interior spaces.

8. Ceramic Panels:

Ceramic panels are a sophisticated choice, combining the aesthetics of ceramics with the benefits of composite materials. These panels consist of a ceramic top layer bonded to a composite backing. Ceramic panels offer high resistance to UV rays, weathering, and graffiti, making them suitable for exterior cladding in urban environments.

9. Gypsum Composite Panels:

Gypsum composite panels comprise gypsum plaster sandwiched between layers of paper or other facing materials. They are used for interior applications such as wall partitioning and ceiling panels due to their fire resistance, sound insulation properties, and ease of installation.

What is a composite panel?

Types of Composite panels, also known as sandwich panels, are a popular construction material consisting of an insulation core sandwiched between two metal or plastic facings.

What are Lpcb approved panels?

What is an ‘LPCB approved’ panel? An LPCB approved panel is one which has been certified by the Loss Prevention Certification Board and is included in the List of Approved Products and Services issued by the Loss Prevention Council. Relevant standards are LPS 1181 and LPS 1208.

How do you identify composite panels?

Notice that there is a gap along the ridged areas of the panel. Tapping and/or pressing the ridge will at least allow you to determine whether the panel is a composite panel, or a built-up system, as the ridge will have some give when pressed. It still does not allow you to determine what the insulation material is.

Why use composite panels?

Types of Composite panels are known for having a high compressive strength, meaning that they have the capacity to bear higher weight loads than other materials. They also have extremely good impact resistance.

Why are composites better?

Composites never rust, regardless of their environment (though they are prone to corrosion when bonded to metal parts). Composites have less fracture toughness than metals but more than most polymers. Their high dimensional stability allows them to maintain their shape, whether hot or cold, wet or dry.

Composite panels have revolutionized the architectural and construction landscapes, offering an array of choices that cater to diverse needs and creative aspirations. From enhancing energy efficiency with IMPs to adding a touch of elegance with ceramic panels, each type of composite panel brings a unique set of attributes to the table. As the construction industry continues to evolve, composite panels stand as a testament to the marriage of innovation and design, transforming spaces into functional works of art.