In the world of architecture and construction, materials play a pivotal role in determining the success of a project. One material that has been gaining significant attention and popularity in recent years is lightweight composite panels. These panels offer a wide range of benefits that have transformed the way architects, builders, and designers approach their projects. In this exploration of the advantages of lightweight composite panels, we’ll delve into the reasons behind their growing popularity and their transformative impact on modern design.

Understanding Lightweight Composite Panels

Before we delve into their benefits, let’s first understand what lightweight composite panels are. These panels are typically constructed by bonding together two thin but stiff outer layers, often made of aluminum or other metals, with a lightweight core material in between. This core material can vary and may include materials like polyethylene, honeycomb structures, or foam. The result is a panel that is both strong and lightweight.

The Benefits of Lightweight Composite Panels

Weight Reduction:

As the name suggests, the primary advantage of these panels is their reduced weight. Compared to traditional materials like solid aluminum or steel, lightweight composite panels can weigh significantly less. This reduction in weight translates into various advantages.

Enhanced Structural Integrity:

Despite their lower weight, lightweight composite panels are engineered to maintain high structural integrity. They can withstand heavy loads, making them suitable for a wide range of applications, from building facades to aerospace components.

Energy Efficiency:

In construction, lightweight panels can reduce the overall weight of a building, which can lead to improved energy efficiency. A lighter building requires less energy for heating, cooling, and transportation of materials.

Ease of Installation:

Their reduced weight makes lightweight composite panels easier to handle and install. This can result in reduced labor costs and shorter construction timelines.

Design Versatility:

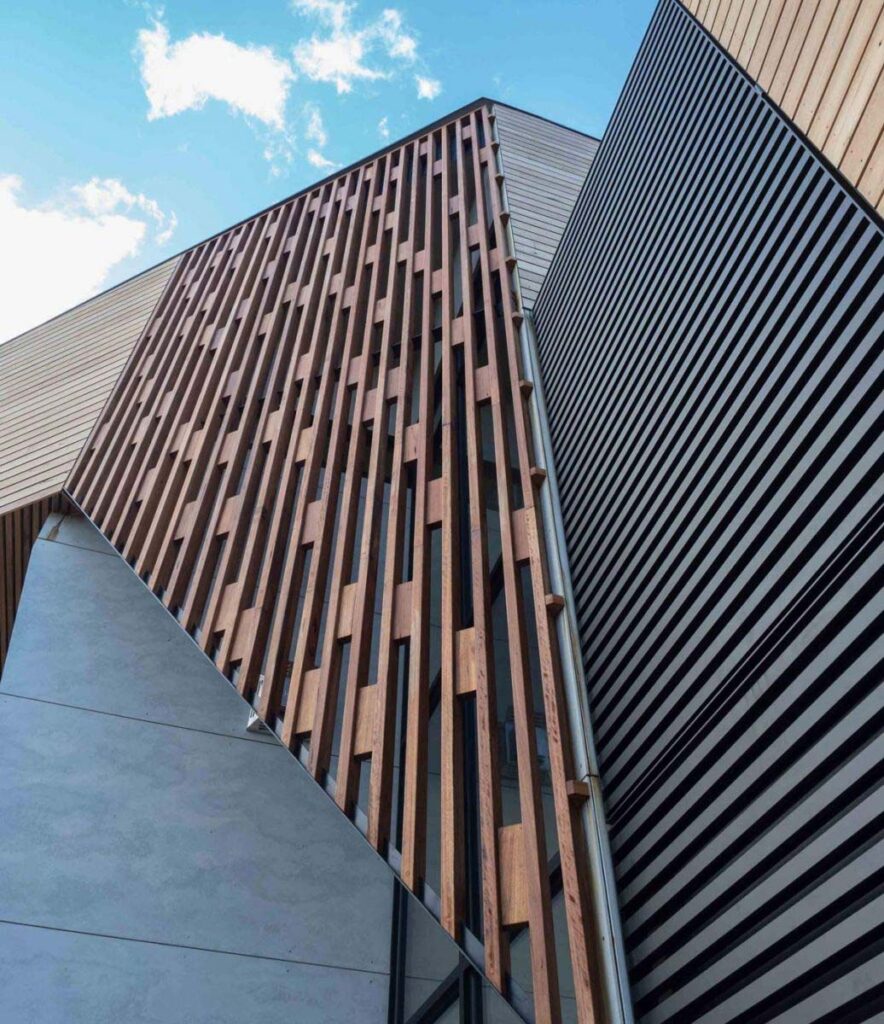

Lightweight composite panels offer architects and designers greater freedom when it comes to shaping their visions. They can be easily cut, curved, or formed into various shapes, allowing for creative and innovative designs.

Corrosion Resistance:

Many lightweight composite panels feature outer layers made of aluminum, which is naturally corrosion-resistant. This makes them ideal for outdoor applications, such as building facades, where exposure to the elements is a concern.

Insulation Properties:

Some lightweight composite panels have excellent insulation properties, which can contribute to energy-efficient building designs. They can help regulate interior temperatures, reducing the need for heating or cooling.

Acoustic Performance:

Depending on the core material used, lightweight composite panels can provide acoustic benefits. They can dampen sound, making them suitable for applications in environments where noise control is essential.

Sustainability:

Lightweight composite panels can be more sustainable than traditional materials. Their reduced weight can lead to lower transportation emissions, and they can often be recycled at the end of their lifespan.

Applications of Lightweight Composite Panels

The versatility and benefits of lightweight composite panels have led to their adoption in various industries and applications, including:

Building and Construction: These panels are used for facades, roofing, interior partitions, and even entire building envelopes.

Transportation: Lightweight composite panels are used in automobiles, trains, ships, and aircraft to reduce weight and improve fuel efficiency.

Furniture and Interior Design: They are employed for creating modern and durable furniture pieces and interior design elements.

Aerospace: In aerospace engineering, these panels are used to create lightweight yet strong components for aircraft and spacecraft.

Industrial Equipment: Lightweight composite panels are used to manufacture equipment components that require strength and durability without excessive weight.

1. What are lightweight composite panels, and how are they constructed?

Lightweight composite panels consist of two thin, stiff outer layers bonded with a lightweight core material, such as foam or honeycomb structures.

2. What is the primary advantage of using lightweight composite panels in construction and design?

The primary advantage is their reduced weight, which has a wide range of positive implications for various applications.

3. Are lightweight composite panels strong enough for structural applications?

Yes, lightweight composite panels are engineered to maintain high structural integrity despite their reduced weight. They can withstand heavy loads.

4. How do lightweight composite panels contribute to energy efficiency in construction?

Lightweight panels reduce the overall weight of a building, leading to improved energy efficiency. Lighter buildings require less energy for heating, cooling, and transportation of materials.

5. Are lightweight composite panels easy to install?

Yes, their reduced weight makes them easier to handle and install. This can result in reduced labor costs and shorter construction timelines.

The advantages of lightweight composite panels, from weight reduction to enhanced structural integrity and energy efficiency, have made them a game-changer in modern design and construction. Architects and builders continue to explore innovative ways to leverage these panels to create sustainable, efficient, and aesthetically pleasing structures. As technology and materials science advance, the potential applications of lightweight composite panels are bound to expand, ushering in a new era of design possibilities and environmental consciousness in the built environment.